Synopsis

Richard will share learnings benefits and insights into an integrated beef supply chain model. He will also outline how working together, and by focussing on genetics, we can combat some of the challenges and avail of new opportunities as we face into the future.

ABP & Blade Farming

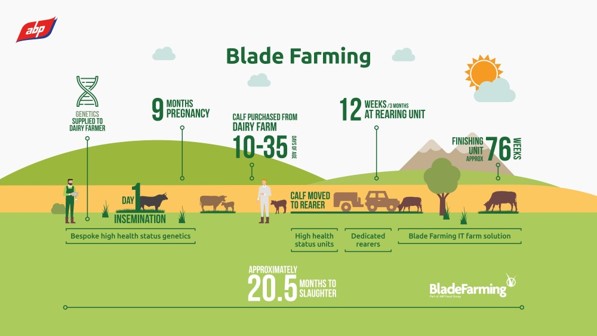

ABP UK are a food business that specialises in the supply and development of award-winning British and Irish beef and lamb products for retail, foodservice and wholesale. ABP UK have 16 operating sites, processing approximately 650,000 cattle and 1.2 million sheep annually, making up 20% and 7% of the national kill respectively. Blade Farming, part of ABP Food Group, was established in 2001 as the first truly integrated beef supply chain in the UK. The Blade Farming model, as shown in figure 1, has been tried and tested for over two decades and offers a high health & welfare system to deliver consistent quality raw material to customer specifications.

Figure 1 Blade Farming

The supply chain benefits of an end to end beef operation

As shown in table 1, there are benefits for all supply chain stakeholders of an end to end beef operation, including the farmer, processor, retailer and consumer.

|

Farmer

|

Retailer

|

|

Processor

|

Consumer

|

Table 1 The supply chain benefits of an end to end beef operation

Genetics

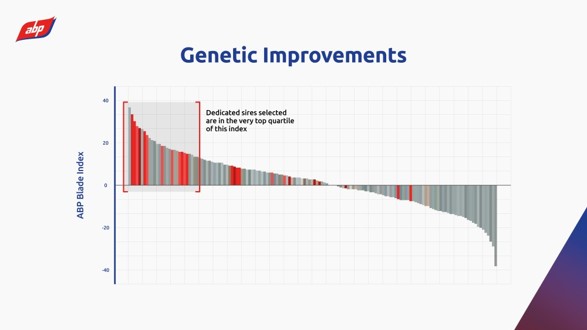

Blade Farming have breeding schemes in place using the best genetics available and encourage calf suppliers to take advantage of these genetics to produce calves that will command a premium in the marketplace. More recently, top Aberdeen Angus genetics have been secured, using DNA tested sires that are proven to have some of the best growth potential and eating quality in the world. As shown in figure 2, dedicated sires selected for Blade Farming schemes are in the very top quartile of this index.

Figure 2 Blade Farming Genetic Improvements

End to end beef operation example: Gamechanger

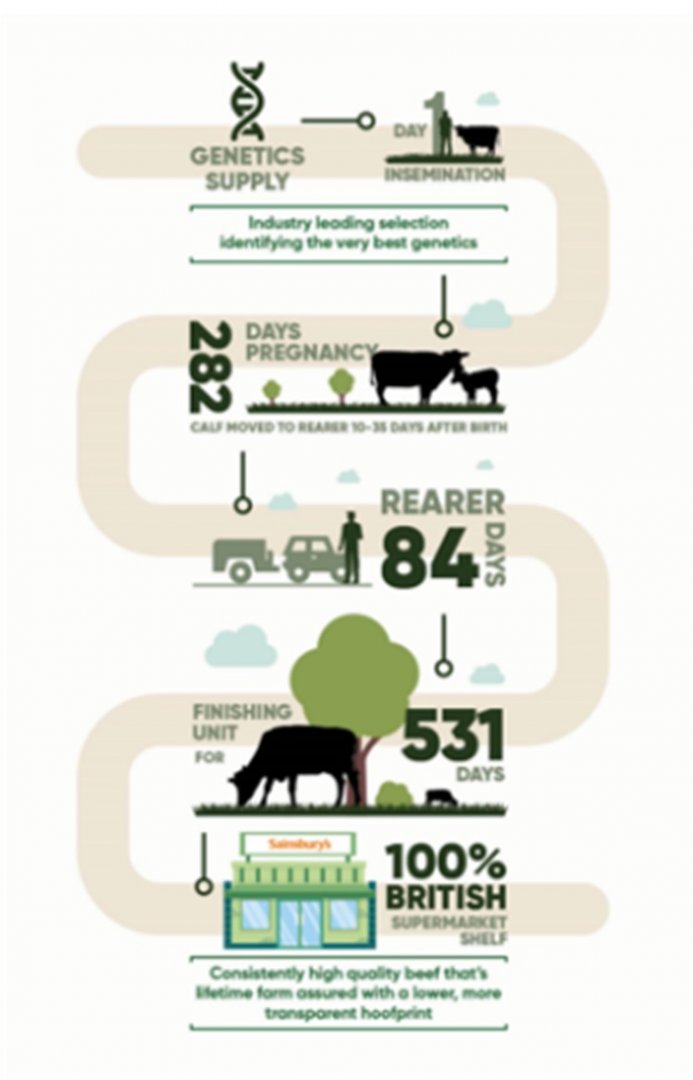

In 2012, Sainsbury’s were the first British retailer to establish an integrated beef supply chain to explore the opportunities and challenges associated with integrated beef production. Years of learnings and insights from this, proved the value of integrated production and formed the foundations for what a new, bigger, integrated supply chain should look like. The Gamechanger integrated supply chain, as shown in figure 3, started in August 2019, in partnership with ABP Food Group. Gamechanger is all about providing farmers with greater security and stability, embracing the very best in Aberdeen Angus genetics, and delivering amazing, consumer-friendly British beef with transparency, traceability and reduced environmental impacts.

Unique aspects of Gamechanger:

- Guaranteed forward pricing mechanism for dairy farmers, rearing and finishing farmers.

- Exclusive, industry leading genetics.

- Finishing farmers paid a management fee instead of a p/kg, known before animals arrive on farm and locked in for the lifetime of the animal.

- Finishing farmers have no capital outlay as cattle are financed through a 3rd party, unlocking working capital.

- Finishing farmers receive free farm management software.

- Opportunities for producer knowledge transfer and to engage in research and development.

Figure 3 Gamechanger

Sustainability

ABP UK are working on a number of projects internally and with industry to support the environmental and economic sustainability of the industry. Launched in 2022, PRISM 2030 is a data driven initiative to improve the sustainability of red meat within the decade. Carbon Trust analysis shows that in common with other meat and dairy supply chains, 90% of the greenhouse gas footprint resides at farm level, 2% with processor, 4% with retailer and 4% with consumer. Therefore, ABP UK will be collaborating with a cross section of 350 beef and lamb supplier farmers, across all different sized farms, to explore how the UK beef and lamb sectors can make a step-change in sustainability. PRISM 2030, will be data driven, starting with carbon footprinting across all farms and then progressing to soil health, animal health, carbon, water and biodiversity with smaller interest groups, over a period of 2-3 years. ABP UK will then work with research partners at The Andersons Centre and Harper Adams University to compile, analyse and interpret the data.

Summary

Integrated supply chains have been operating in other sectors, such as pork and poultry, for some time. However, beef supply chains are more complex due to the lifetime of the animal and commitments required by all participants. Joining an integrated supply chain, such as Gamechanger, can offer significant benefits, as long as everyone involved works to a set of protocols. A truly integrated supply chain involves commitment from the customer to have integrity for the long term. Established models can share more information which may offer the benefits needed to make a qualified business decision.

Photography Credit @Jenny Wood Photography