Summary

- 100-cow suckler herd bringing all progeny to slaughter.

- Cows are all first-cross Angus and Hereford bred from the dairy herd.

- Targeting terminal traits in sires, as milk yield is not a problem and no replacements retained.

- 91% in-calf rate in 2018 from 11 week breeding season.

- 100% AI used in 2018.

Introduction

Newford Farm is a 100-cow suckler-to-beef herd established by DawnMeats and Teagasc in 2015 and located in Athenry, Co Galway, in the west of Ireland. The project was set up to demonstrate the physical and financial performance that can be achieved from a suckler herd utilising first-cross cows from the dairy herd and bringing all progeny through to beef.

The management structure of the project is made up of members of Dawn Meats, Teagasc and the Irish Farmers Journal, while McDonalds also provides support for the project. I am the farm manager and work fulltime on the farm, with the support of Michael Fagan, a Teagasc technician, as well as employing a student for three months in spring.

The backbone of the system is to maximise output from grazed grass, with a target set at the outset of finishing 70% to 80% of progeny off grass at an average of 20 months of age.

Ireland has experienced rapid expansion in the dairy herd since 2010, with an abundance of Angus and Hereford progeny available. Milk yield in these first-cross animals is excellent, but a trait that often lets these animals down is their beef characteristics. With this in mind, we decided at the beginning of the project that if we were going to reach our finishing targets, a lot of work needed to go into sire selection and maximising the terminal traits of our progeny. The decision was made to use AI on the cows and use two stock bulls to mop up after six weeks of AI. However, the success of AI was such that we sold the two stock bulls in 2017 and switched to 100% AI.

Why I use AI

As stated, the cows on this farm have good maternal characteristics – they have plenty of milk, are docile and we have found they go back in calf with relative ease. The farm brings all progeny to slaughter and AI is a proven reliable tool to utilise the best terminal genetics available. The cow brings the milk to the table and by crossing with high-reliability terminal bulls with good carcass weight and conformation breeding values, we have an excellent grassbased finishing animal. Trait reliability is a key component because high reliable terminal sires will have calves on the ground that will hit their performance targets and hopefully leave profit on the farm. Reliability is also of great concern when it comes to calving ease, with a major component of the system to have cows calving with minimum intervention.

Putting theory into practice

The main focus for me before I start breeding is the condition of cows. We know that for a cow to start cycling as soon as possible after calving that she should be at a body condition score of between 3 and 3.5 at calving. Therefore, preparation for breeding in the Newford herd commences at housing or shortly after. Cows are penned according to their body condition, allowing a feeding programme to be implemented that matches intake with cow nutritional requirements.

With this in mind, we identified 36 cows at housing in November 2018 and fed 3kg of soya hulls until mid-January. This level of supplementation is higher than previous years, but takes account of lower-quality silage, while there are a greater number receiving supplementation due primarily to spring and summer drought being hard on young cows and those rearing twin calves. This relatively short period of concentrate feeding has cows in better condition at calving and we have found cows return to heat much quicker. Maintaining a tight calving interval will far exceed the cost of supplementing cows with concentrates.

At Newford, the aim is to get cows and calves outdoors as soon as possible after calving. The spring of 2018 presented lots of challenges in this regard, with difficult ground conditions and poor grass growth preventing early turn-out of all groups. Cows were prioritised over steers and heifers and once weather conditions improved cows and calves quickly settled.

At the beginning of April, cows were already seen coming into heat and their tag numbers were recorded daily as part of routine herding. Weather and ground conditions were excellent and I was encouraged by the number of cows showing heats. The breeding season began on 24th April and AI was used for 10 weeks only. We deliberated on extending this to 11 weeks, given the challenging spring, but had found in previous years that there were very few cows served in weeks 10 and 11, so we stuck with our decision.

Heat detection is the key to a successful outcome when using AI. Two heat detection aids are used in Newford farm – tail painting and vasectomised bulls, while regular supervision is also a critical component. We use tail paint on the cows to see which cows are coming into heat. This is a very cheap and effective way to see which animals are in heat. We top this up with a different colour as cows are served and as required during the breeding season.

We also use vasectomised Friesian bulls during the breeding season, with one bull run with each group of 50 cows. We purchased the vasectomised bulls for 850 Euros each in 2018 and kept them in quarantine for three weeks before letting them out with the two groups of cows.

The day they arrive on the farm, they enter quarantine and are blood tested. The bloods are then sent for analysis to Enfer Scientific to do a full health check, with bulls remaining segregated from the herd until clear results are returned. A chin-ball harness with paint is fitted to each bull (this leaves a paint mark on the rump of the cow when the teaser is mounting the cow or resting his head on her rump).

The teasers are let out with the cows at the start of the breeding season. In 2018, one of the bulls was quiet for the first week, but as more cows came into heat, he became quite active and both bulls did an excellent job marking the cows.

Once-a-day AI was used in 2016 and it was so successful that I have continued this method. The way we work once-a-day AI in Newford is cows are served every day at noon. If a cow is in standing heat in the evening or morning, she is served at noon. If she is still showing standing heat in the evening after being inseminated earlier in the day, she receives another AI straw the following morning.

It is important to point out that in 2016 an AI technician was called to the farm daily. Since then, I have become fully trained in the technique and I carry out all insemination on the farm now. Regular monitoring is also an important component of AI. Cows are checked at least five times daily and any cows in heat are separated from the group in the morning.

Cows are docile and with the help of reels, a paddock system and a farm roadway, this task is completed quickly each morning without too much stress to man or beast. I was very sceptical of going down the AI route, especially with two very good bulls on the farm. It takes time to check and get cows into the yard, but, in my opinion, the calves on the ground and their performance have more than convinced me of the advantages of using AI.

The 10-week breeding period in 2018 and the scanning results on 2nd August show:

- 91 cows in-calf out of 100 bred, a 91% in-calf rate.

- 60 cows held to first service.

- 20 cows held to second service.

- 11 cows held to third service.

- Four sets of twins scanned.

- Nine cows empty.

I am very happy with the results showing 91 out of 100 cows bred incalf. One of the key components of a profitable suckler system is that cows are in-calf and a tight calving spread is maintained. This in turn means you have a weanling, store or finished animal to sell at the end of the year. I was also pleased that 60 cows held to the first service, which means we will continue to have a very busy calving period this February. The empty rate of 9% is well below the national average and I would be quite satisfied if I achieve this annually.

Sire selection

One of the most important jobs I do each year is to select the terminal sires that we use on the herd. These are key decisions, as the progeny of these bulls will be finished on the farm. It is critically important that the sires are easy calved and deliver progeny that have good growth rates, perform well at grass, have conformation, kill out well and, most importantly, leave profit on the farm. This is why each year I will spend a few evenings looking over the Irish Cattle Breeding Federation (ICBF) list of terminal sires. There is a very simple filter function on the list of AI bulls that allows a farmer to identify bulls with traits that are desired. By inputting the desired selection criteria into the computer search option, it will highlight in seconds the available bulls.

The criteria for sire selection on Newford Farm has been:

- Five-star terminal index.

- >80% reliability.

- <7% calving difficulty for mature cows.

- >30kg predicted carcass weight for mature cows.

- <6% calving difficulty for the 1st and 2nd calvers.

- >25kg predicted carcass weight for 1st and 2nd calvers.

- Straw costs less than 15 Euros.

This is time well spent on any farm and it allows me to pick and choose the bull to suit my type of cows; i.e. AA/HF with an average weight of 655kg. It is also worth noting that we make the decision based on the sire’s terminal figures and sire breed is not a factor in this decision. Figure 1 shows the sires used in 2018.

Figure 1: Sires used in 2018.

We had used Fiston and Gammin in 2016 and are very happy with their calves on the ground at the moment. They were easily calved, have good shape and are performing exceptionally well on the cows. When these came up on the 2017 and 2018 list, we were happy to use them again. Another bull that we tried for the first time in 2017 is Willodge Goldcard and we chose him because he has exceptional figures for calving (4.6%), carcase weight (31kg) and reliability of 87%.

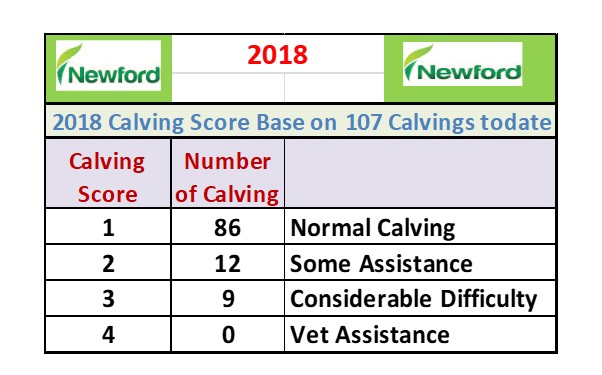

Calving score 2018

A strong focus on calving ease has paid dividends since the project commenced, with calving scores for 2018 listed in Figure 2.

Figure 2: Calving scores for 2018.

Current stock performance

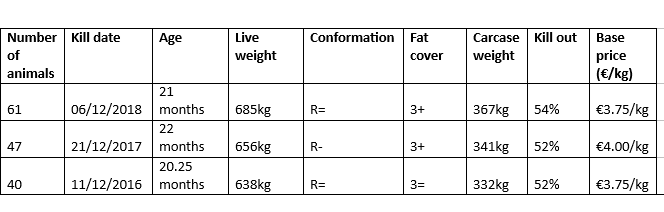

The farm is always trying to maximise performance from every animal and, this year, we have been happy to continue to achieve superior slaughter performance. Table 1 details the slaughter performance of steers for the last three years and reflects this.

Table 1: Steer slaughter performance 2016 to 2018.

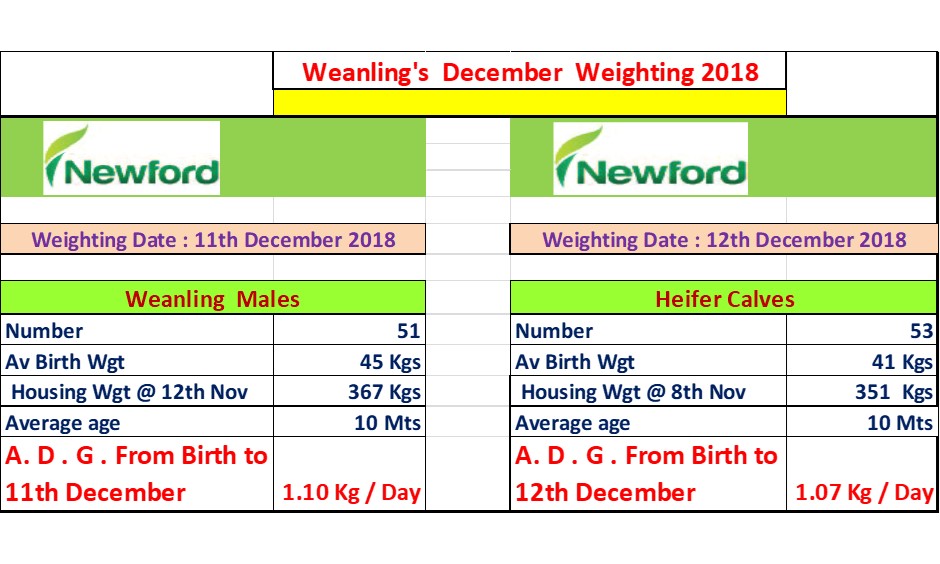

Unfortunately, the benefit of the additional carcase weight in the final sale price was eroded by a lower beef price, but at least we are trending in the right direction with carcase weight. We keep good-quality grass in front of cows, calves and finishing stock at all times. This means that we can incorporate more grass into the animals’ diet and, therefore, produce animals more profitably. The tables below show the most recent weights for each category of stock (see Figure 3).

Figure 3: Performance of 2018-born stock.

Conclusion

Since the start of this project in 2015, we have been trying to maximise performance at every level on the farm – breeding, grassland, health and nutrition. It has become clear that the key to becoming a profitable suckler-to-beef farm is to use the best genetics available and that will work on this farm. In my opinion, to achieve a positive outcome I will use AI on all cows and will be able to predict the type of animal I will have at slaughter. AI might not suit every suckler farmer, but for someone who was quite sceptical in the beginning, I will be sticking with it for the foreseeable future.